OMEGA FLEYEVISION

Please, contact me on this product

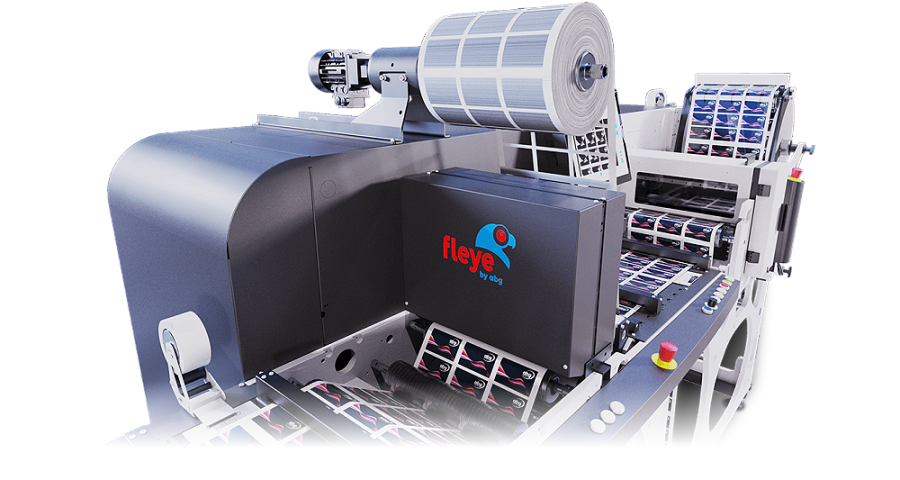

fleyeVision is also unique in that A B Graphic have developed it themselves, to work with our their finishing equipment. This means that everything works seamlessly together, accuracy and reliability are guaranteed. Other manufacturers depend, instead, on third party inspection equipment.

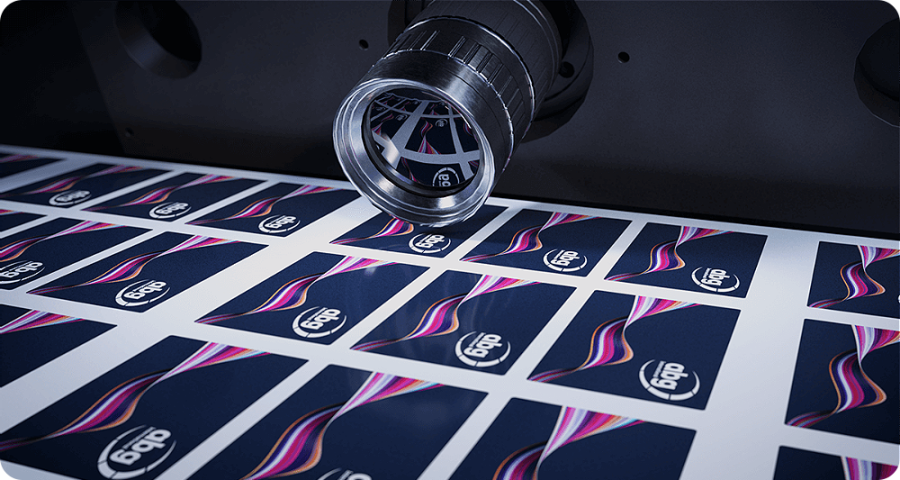

Fast, accurate and fully automated, fleyeVision can be configured to meet your inspection requirements exactly. In addition to checking for scratches, hickeys and letter or text irregularities, it can detect register shifts or colour deviations.

Additionally, modules are available which can: measure gaps, compare labels to a PDF master image, verify codes and numbers, check colours, map faults and document findings to meet individual requirements.

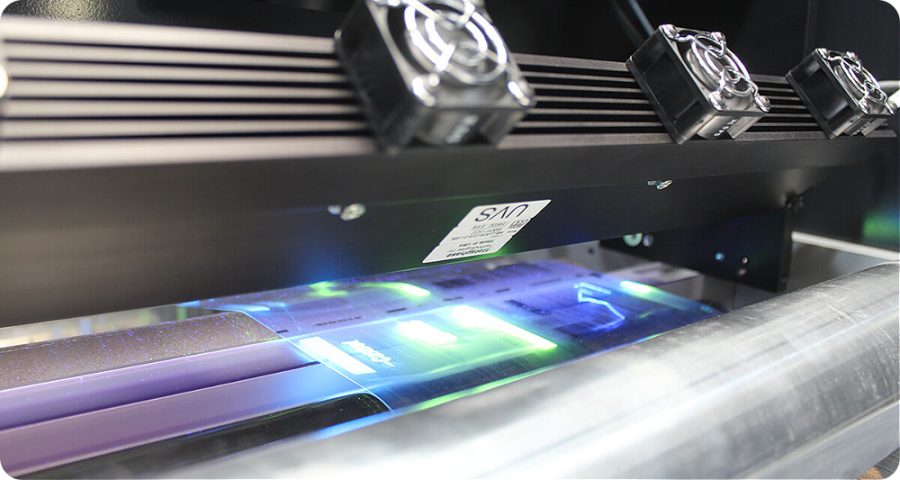

fleyeVision Workflow Manager is also available. This roll mapping facility detects and records errors at the printing or converting stage, which can subsequently be corrected at the downstream rewinder. It can improve processing speeds, avoid waste, guarantee 100% accuracy and eliminate the need for a second inspection system at the rewinder.